A matsayin babban ɓangaren silinda na hydraulic, ana amfani da sandar piston a cikin yanayi mai wuyar kewaye da lalata;Saboda haka, babban kayan kariya mai inganci yana da mahimmanci.A halin yanzu, electroplating hard chrome hanya ce mai yaduwa.Saboda ƙarfinsa mai ƙarfi da ƙarancin farashi, chrome mai ƙarfi na lantarki hanya ce ta gama gari don maganin sandar piston.

Ma'auni na suturar sandar piston

1) Tauri

Tauri shine muhimmin sifa na suturar sandar piston.Rubutun da ke nuna rashin ƙarfi ko rashin ƙarfi ba zai iya ɗaukar ƙarfi da yawa yayin dutsen kusurwa ko ƙwanƙwasa mai ƙarfi ya buge sandar piston, lalacewa ta sama ta faru cikin sauƙi, kuma silinda na hydraulic zai iya kasa yin aiki nan da nan saboda lalacewa ko lalacewa.

Gwajin tasiri wani gwaji ne mai ƙarfi wanda zaɓaɓɓen samfurin yawanci ana buga shi kuma ya karye ta hanyar juzu'i.Gwaje-gwajen da aka fi sani da irin wannan sune gwajin Charpy V-notch da gwajin Izod waɗanda aka bayyana a cikin ASTM E23.Bambancin ƙa'ida tsakanin gwaje-gwaje biyu shine yadda aka gyara samfurin.

2) Juriya na lalata

Saboda yanayin aiki mara kyau, juriya na lalata yana da matukar mahimmanci ga murfin sandar silinda na silinda.Gwajin fesa Gishiri wata hanyar gwaji ce ta al'ada da aka yi amfani da ita don bincika juriyar lalatawar sandar sandar silinda ta silinda;gwajin juriya ce mai saurin lalata kuma ana kimanta bayyanar samfuran lalata bayan wani lokaci.

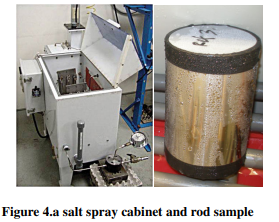

Na'urar gwaji kamar yadda aka nuna a hoto na 4 ya ƙunshi rufaffiyar ɗakin gwaji, inda ake fesa maganin gishiri, galibi maganin sodium chloride, ta hanyar bututun ƙarfe.Wannan yana haifar da gurɓataccen yanayi a cikin ɗakin kuma don haka, sassan da ke cikinsa ana kai hari a ƙarƙashin wannan mummunan yanayi na lalata.Gwaje-gwajen da aka yi tare da maganin NaCl an san su da NSS (fashin gishiri mai tsaka tsaki).Ana ƙididdige sakamakon gabaɗaya azaman awoyin gwaji a cikin NSS ba tare da bayyanar samfuran lalata ba.Sauran mafita sune ASS (gwajin acetic acid) da CASS (acetic acid tare da gwajin jan karfe chloride).Ginin ginin ɗakin, tsarin gwaji, da sigogin gwaji an daidaita su a ƙarƙashin ƙa'idodin ƙasa da na duniya, kamar ASTM B117, DIN 50021, da ISO 9227. Bayan tsawon lokacin gwajin, ana iya ƙididdige samfurin bisa ga tsatsawar farfajiyar ta amfani da daidaitattun bayanai kamar yadda aka nuna. cikin tebur 1.

3) Sanya juriya

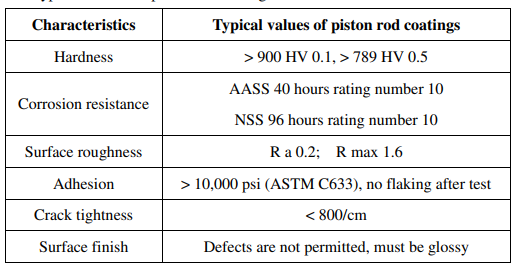

A matsayin naúrar watsa wutar lantarki, sandar fistan yana buƙatar motsawa gaba da baya akai-akai, a lokaci guda lalacewa yana faruwa yayin zamewar saman rufin a kan silinda.Don haka juriya kuma shine muhimmin buƙatu don sandar piston a rayuwa.Taurin saman shine mabuɗin siga don juriya.Bayan tauri, juriya lalata da juriya, bisa ga ka'idodin masana'antu daban-daban da bukatun abokan ciniki, an jera wasu ma'auni na suturar sandar piston a cikin tebur2.

Don ƙarin bayani game da silinda na hydraulic, na'urorin wutar lantarki, da fatan za a iya tuntuɓar mu ta:sales@fasthydraulic.com

Lokacin aikawa: Satumba-23-2022